Additional Details about the Functionality

The additional details about the functionality is provided below:

Order Site’s Lot - While allotting Lot Numbers to Items, the Lots received in Order Site alone are displayed for allotting.

Cost Calculation in various places in system - The Lot selection doesn’t affect the Cost calculation. Current behavior of the system persists.

Barcode Printing - The tags are provided to print:

LOTNO - Use this for including Lot No.

LOTDETAIL - Use this for including Lot Details.

VENDORNAME - Use this for including Vendor Name. If Vendor is not present for Item line then it will be taken from Order header.

EXPIRYDATE - Use this for including Expiry Date.

Data Conversion - Data conversion can be used to update the Lot details of batches of Item(s) received using Quantity data conversion. The following information can be updated to received Batches using data conversion:

Lot Number

Expiry Date

Lot Details

Returning Items - While returning sold non-serial Item having Lot assigned:

Full Return - The Non-serial Item quantity gets returned without prompting the user to select any Lots. The Item quantities get returned to the Lots from where they were allocated and the Lot quantity available for allocating gets updated accordingly.

Partial Return - System will automatically display the View / Select Lot Number window with Lots from where the Item(s) quantity was allotted in the Order, provided:

The Item(s) were allotted from more than one Lot.

The Configuration module > Warehouse tab > Auto Select Lot on Partial Sale Return check box is not selected. (This check box will be in selected state by default on upgrading R2.) If the Auto Select Lot on Partial Sale Return check box is selected then the system automatically allocates the Lot on partial returning of Items.

User has to enter the Lot No. for the returned items against appropriate Lots. System will revert the quantity in the selected Lot for the Item, and this quantity can be used for assigning from other Orders.

Automatic Lot allotting based on Configuration setup - Based on selection within Configuration module > Accounting tab > Inventory Costing Convention for Qty Items the quantity of Item(s) added to an Order get allotted from its Receive lines in the Order Site. This happens on partially filling and shipping Items or while selling Items without allotting Lots for them. When the value selected in Inventory Costing Convention for Qty Items field is:

Average - When the quantity of Item(s) added to an Order is not allotted (or partially allotted) then the quantity (remaining quantity) of Items get allotted from their existing Receive lines in FIFO (First In First Out) format automatically on shipping from Order. This also makes the Receive lines list in the View / Select Lot Number window in Ascending order of their Received Date.

FIFO - When the quantity of Item(s) added to an Order is not allotted (or partially allotted) then the quantity (remaining quantity) of Items get allotted from their existing Receive lines in FIFO (First In First Out) format automatically on shipping from Order. This also makes the Receive lines list in the View / Select Lot Number window in Ascending order of their Received Date.

LIFO - When the quantity of Item(s) added to an Order is not allotted (or partially allotted) then the quantity (remaining quantity) of Items get allotted from their existing Receive lines in LIFO (Last In First Out) format automatically on shipping from Order. This also makes the Receive lines list in the View / Select Lot Number window in Descending order of their Received Date.

Note: Automatic Lot allotting of the quantities of Item transferred using an Inventory Transfer Order gets allotted in LIFO format irrespective of the setup in Configuration module.

Receive Report - The Lot Number information of Item is included in the Receive Report.

Splitting of an Item line - The original Item line/first line retains the Lot Number allotted. Lot Number re-distribution is not supported.

P-Assign - On receiving Items on a linked PO, system does not automatically allot the Lot Number for the linked Order lines.

On Marking Item Line with Lot allotted as Not Available - The Item line retains the allotted Lot Number.

Allotting Lot Number based on Item line Status - No restrictions for allotting Lot number for any non-serial sell item line, which is in any Status other than in Deleted status.

Deleting Line and Mark as Deleted - The deleting of Order's Item lines/mark the Item lines as Deleted, is not allowed, if Lot number is assigned for the Item line quantities. Appropriate error message gets displayed as "R2_00879:Unable to Delete". Clicking on Details button displays the detailed message as "R2_01337:Cannot delete, as Lot Number(s) are selected for this item.".

Invoicing - The system allows allotting Lot Number to Item lines even if the Item line is added to an Invoice or not.

Assigning Lot Number while Receiving - The Lot Number can be assigned to Serial/Non- serial/Hybrid Items while being received irrespective of whether it is sellable or not.

Hybrid Items - The system will allow setting the Lot number while receiving the Hybrid Items (Non- serial Items having with Assets check box selected). However, allotting Lot number on Orders, is not allowed for Hybrid Items.

Serial Kits - Allotting Lot number is not allowed for Serial Kits and their child serial/non-serial Items.

Non-serial Kits - Lot number can be allotted to Non-serial child Items with Action as Sell, of a Non-serial Kit added to an Order with Action as Sell.

Conversion of Orders from Quote to Hold to Reservation - Conversion of Order status from Quote to Hold to Reservation or vise versa retains the lot allotting done for various Item(s) in the Order.

Cancelling of Orders having Item(s) added with their Lot allotted - Cancelling of Orders having Item(s) added with their Lot(s) allotted reverts the Lot allocation to the respective Lot(s) of the Item(s), and the reverted quantity in the Lot(s) can be used for allotting in other Orders.

On partially filling and shipping the item in a Sale Order - Click here to read a sample scenario of Lot allotting on partially filling and shipping Item on a Sale Order.

Prerequisite:

Select the Configuration module> Accounting tab > Inventory Costing Convention for Qty Items

as Average/FIFO.

Scenario 1:

Create a Non-serial sell item [BMP-04] and receive 10 quantities each in two Lots.[Lot#1] and [Lot#2].

Create a Sale Order [ORDER#1] and add 15 quantities of item [BMP-04] to the order. Allot lot as 8 quantities from [Lot#1] and 7 quantities from [Lot#2].

Now go to Fill Order window and fill 12 quantities of [BMP-04] from the Order.

Ship the 12 quantities of Item [BMP-04] from Ship Order window. The Order [ORDER#1] will have two item lines, one with 12 quantities of [BMP-04] with Status as Sold and other with 3 quantities of [BMP-04] with Status as Reserved.

Select the [BMP-04] Item line with 12 quantities with Sold Status and right-click > View/Select Lot Number command. System displays following Lot related information:

Lot#1 - Received Qty = 10 Allotted Qty = 0 Remaining Qty = 2 Selected Qty = 8

Lot#2 - Received Qty = 10 Allotted Qty = 3 Remaining Qty = 3 Selected Qty = 4

Select the [BMP-04] Item line with 3 quantities with Reserved Status and right-click > View/Select Lot Number command. System displays following Lot related information:

Lot#1 - Received Qty = 10 Allotted Qty = 8 Remaining Qty = 2 Selected Qty = 0

Lot#2 - Received Qty = 10 Allotted Qty = 4 Remaining Qty = 3 Selected Qty = 3

Scenario 2:

Create a Non-serial sell item [BMP-05] and receive 10 quantities each in a single Lot [Lot#1].

Create a Sale Order [ORDER#1] and add 10 quantities of item [BMP-05] to the order.

Allot lot as 5 quantities of the Item [BMP-05] from [Lot#1].

Now go to Fill Order window and fill 7 quantities of [BMP-05] from the Order.

Ship the 7 quantities of Item [BMP-05] from Ship Order window. The Order [ORDER#1] will have two item lines, one with 7 quantities of [BMP-05] with Status as Sold and other with 3 quantities of [BMP-05] with Status as Reserved.

Select the [BMP-05] Item line with 7 quantities with SoldStatus and right-click > View/Select Lot Number command. System displays following Lot related information:

Lot#1 - Received Qty = 10 Allotted Qty = 0 Remaining Qty = 3 Selected Qty = 7

Select the [BMP-05] Item line with 3 quantities with ReservedStatus and right-click > View/Select Lot Number command. System displays following Lot related information:

Lot#1 - Received Qty = 10 Allotted Qty = 7 Remaining Qty = 3 Selected Qty = 0

CID for Lot Number in Invoice Prints - The CID 8615 to print Lot Number is provided for Invoice Prints. Click here, for viewing a sample Invoice print UI file.

Non-serial Sell Item line on an Order whose Depreciation is posted - The system won't allow to allot Lot Number or modify already allotted Lots for a Non-serial Sell Item line on an Order whose Depreciation is already posted. However, the Lot(s) if already allocated for the Non-serial Sell Item line on the Order can be viewed by accessing the View / Select Lot Number window, for the Item from the Order.

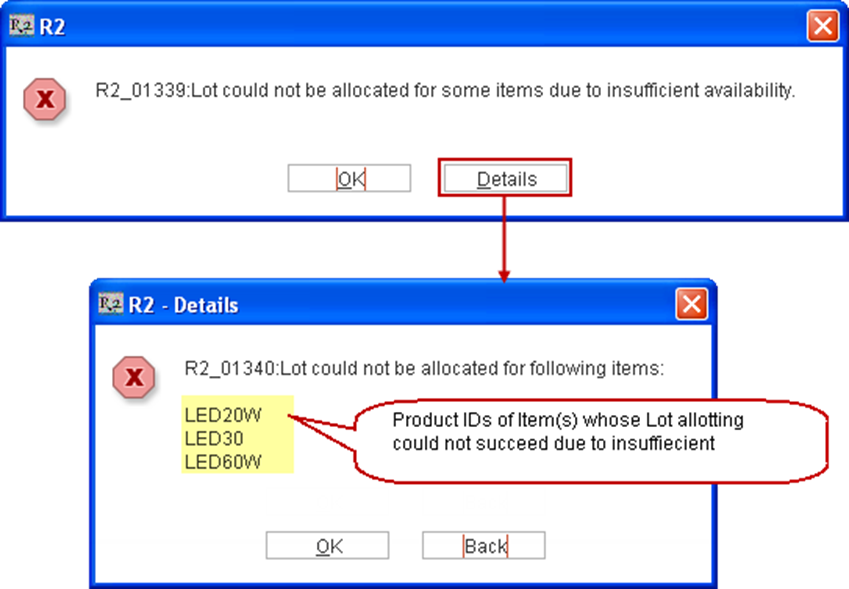

Multi-user scenario of allotting Lot Number - If multiple users try to allot from the same Lot for the Item added to one or more Orders, the Lot get successfully allotted for the first user who clicks OK icon in View / Select Lot Number window. Subsequently when the second user, who also selected the Item from the same Lot (but whose quantity is not available sufficiently now), gets prompted saying ”R2_01339:Lot could not be allocated for some items due to insufficient availability." with OK and Details button. Clicking on Details button displays the details of the Item(s) whose Lot couldn't be allotted as shown in Figure 3.0.

Figure 3.0 Message with Item(s) details whose Lot Allotting failed due to Insufficient Availability

Releasing extra allotted quantity of Item while dispatching the Item - While selling an Item, the extra allotted quantity of the Item will be released by the system and an entry is made in the Exceptions window. Click here to read the sample scenario of releasing the extra allotted quantity of Item while dispatching the Item.

Scenario:

Create a Non-serial sell item [BMP-06] and receive 10 quantities each in a single Lot [Lot#1] with Batch ID [Batch#1].

Create a Sale Order [ORDER#1] and add 5 quantities of item [BMP-06] to the order. Allot 10 quantities of Item [BMP-06] from [Lot#1].

Select View menu > Fill Order. The Order Fill window is displayed.

Fill and Ship 5 quantities of the Item [BMP-06], in the Order [ORDER#1] from the Order Fill window.

Exit the Order Fill window. The prompt message "Exceptions found during scanning. Do you want to view it now?'" is displayed with Yes and No options.

Click Yes. The Exceptions window gets displayed with the Exceptions entry ”Extra allotted quantity released by system from: Batch (Batch#1), Lot (Lot#1)” which is made for releasing the excess 5 quantities of the Item [BMP-06] allotted on the Order [ORDER#1].

Note: The prompt message for viewing the Exceptions will also be displayed on exiting the Ship Order window if Item(s) are shipped from Ship Order window.

Re-assigning extra allotted quantity of Item in an Order to another Order while dispatching the Item - While selling an Item, the extra allotted quantity of the Item in another will be released by the system and an entry is made in the Exceptions window. Click here to read the sample scenario of re-assigning excess allotted quantity of Item while from an Order to another Order while dispatching the Item.

Scenario:

Create a Non-serial sell item [BMP-06] and receive 10 quantities in a single Lot [Lot#1] with Batch ID [Batch#1].

Create a Sale Order [ORDER#1] and add 5 quantities of the Item [BMP-06] to the Order [ORDER#1].

Allot 10 quantities of Item [BMP-06] from [Lot#1] in [ORDER#1].

Do not Fill or Ship the Item [BMP-06] on the Order [ORDER#1].

Create another Order [ORDER#2] and add 5 quantities of the Item [BMP-06] to the Order [ORDER#2].

Select View menu > Fill Order. The Order Fill window is displayed.

Fill and Ship 5 quantities of the Item [BMP-06] in the Order [ORDER#2]. The excess quantity previously allotted on the Order [ORDER#1] is automatically re-assigned to the Order [ORDER#2].

Exit the Order Fill window. The prompt message "Exceptions found during scanning. Do you want to view it now?'" is displayed with Yes and No options.

Click Yes. The Exceptions window is displayed with the Exceptions entry ”Lot Re-assigned by system from: Order (ORDER#1), Batch (Batch#1), Lot (Lot#1)” .

Note: The prompt message for viewing the Exceptions will also be displayed on exiting the Ship Order window if Item(s) are shipped from Ship Order window.

Open the Order [ORDER#1] > View menu > ChangeHistory > ViewExceptions icon. The Exceptions window is displayed with Exception entry "Lot Re-assigned by system to: Order (ORDER#2), Batch (Batch#1), Lot (Lot#1)" which is the exception entry regarding the excess quantity allotted on [ORDER#1]being automatically re-allotted by the system to [ORDER#2].

Feature Revision History

Revision No | Changes in Feature | Version | Reference ID |

1 | Selecting Lot for Non-serial Sell Items | 05.70.02- 00 | 27196 |

2 | Selecting Lot for Non-serial Sell Items in Inventory Transfer Orders | 05.70.03- 00 | 27196 |

3 | Additional Columns in Lot Details Window | 05.70.03- 00 | 27366 |

4 | Change in Configuration Check Box Name to Auto Select Lot on Partial Sale Return | 05.80.00- 00 | 27486 |